Blind spots in PLC programming: A wake-up call for the industry

Few like to address it, but the numbers speak for themselves: According to the 2022 Senseye study, unplanned downtime and production stoppages are...

%20(4)%20(1).png)

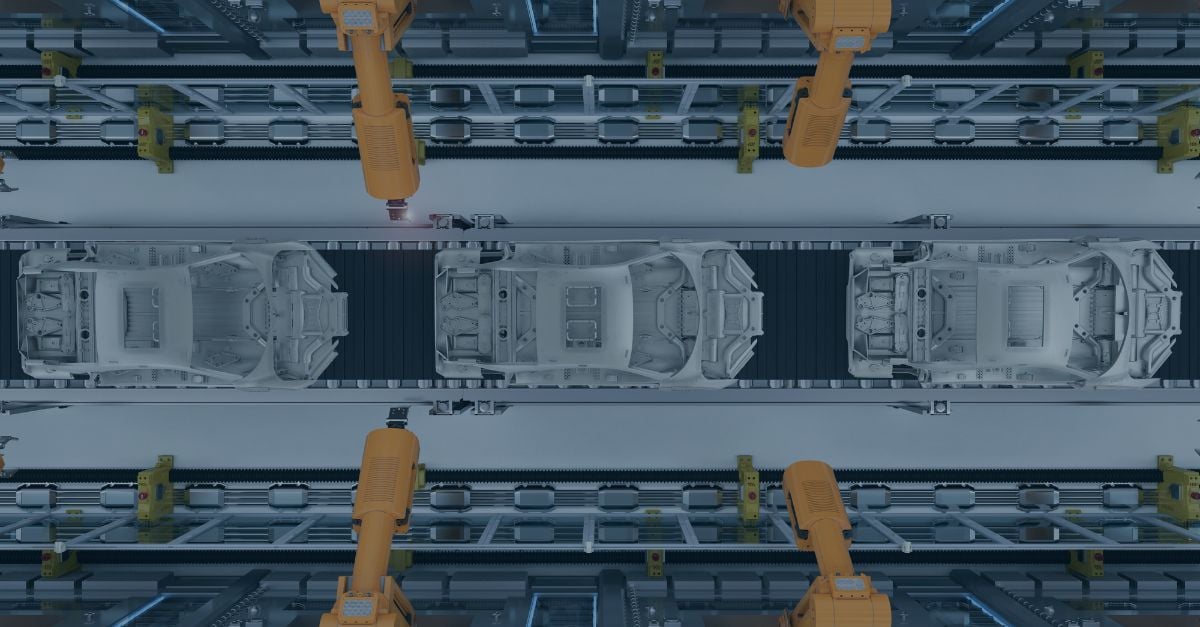

Industry 4.0's increasing digitization requirements force automation technology to rethink how machines are programmed today.

In this increasingly complex environment, you wish for nothing more than for the machine to function as programmed after a lengthy programming process and endless feedback loops. Moreover, the machine should perform all desired functions and be reliable in production. At the moment, however, it is impossible to meet these demands.

Due to the almost infinite possibilities of machine states, it is impossible to define all possible states with manual programming. In addition, various standards are used in the industry, which creates dependencies and challenges within the supply chain.

The Selmo Solution has the answers to the problems mentioned above. This way machines become reliable, and dependencies on market conditions get reduced.

Imagine the process of buying a new machine. At this point, think of any past projects. Think back to the process from the project start all the way to commissioning. With which obstacles were you confronted? Which challenges did you have to face? Now you probably have a vivid recollection of the tedious journey to commissioning.

What if there was a way to make this journey simpler? Keep reading, and we will show you how. #simplySelmo

%20(3)%20(1).png?width=531&height=299&name=%23einfach%20mit%20Selmo%20-%20Kampagne%20(1920%20%C3%97%201080%20px)%20(3)%20(1).png)

What’s simpler than

The acquisition of a new machine still follows this order: First, the mechanical engineer is involved in mechatronics. In the next step, electronics are considered regarding sensors and actuators. Finally, the software programming comes into play, which is presented with a fait accompli needing to work out how to get the required functions into the machine.

The current problem is that these three domains are considered individually. As a result, synergies are lost. Especially PLC programming ends up with a huge challenge. Yet there is one component that unites these domains, namely logic.

Selmo rethinks this process: we start by asking ourselves what the machine must be able to do and model the process. We apply the logic. The Selmo Solution automatically translates the process into a bit pattern, generating your software ready to use without writing a single line of code. The next step is to derive logical requirements for mechatronics and electronics. With Selmo, there is a logical process for the entire machine building.

What’s simpler than

Currently, many companies have various standards in use due to different manufacturers. This causes confusion and countless training or retraining when standards are changed. The bottom line is that a lot of time is spent catching up repeatedly. This ties up important resources and freezes innovation.

Now imagine if there was a generic standard that could be applied to the entire industry. Our Selmo Standard creates exactly this uniform and clear structure, which makes programming a machine much easier. By choosing Selmo, 50 percent of your program structure is already in place.

What’s simpler than

As already mentioned at the beginning, in conventional machine programming allowed and not allowed states are defined. However, due to the state explosion problem, it is not feasible to completely define and subsequently program all non-allowed states. Conversely, this means that there is room for coincidences, which are a major source of errors. In addition, the software is in an ACTUAL state, which is not comparable with the ACTUAL state in which the machine is. This means that even if your machine is (still) running or shows no errors, it is not necessarily running error-free. It only means that no error has appeared yet that has been programmed.

Selmo can determine whether the machine's state is correct or incorrect at any time. We focus on the process model and translate the process as an allowed bit pattern to define all states. At the same time, all other states are automatically defined as invalid. Thus, any deviation can be detected immediately. The process model serves as the TARGET state and the machine as the ACTUAL state. This target-actual comparison of software and machine in real time gives you the certainty that when the machine runs, it is acting correctly.

%20(5)%20(1).png?width=575&height=323&name=%23einfach%20mit%20Selmo%20-%20Kampagne%20(1920%20%C3%97%201080%20px)%20(5)%20(1).png)

What’s simpler than

Currently, there are still countless dependencies due to different standards and a limited supply of suppliers & PLC programmers. This results in projects with eternally long waiting times, endless training courses, and a lack of resources.

By reducing the complexity and the simple and uniform handling through our Selmo Standard, it is finally possible to become more independent from current market conditions. This creates space to concentrate on the essentials again, releases potential for innovations, and ultimately gives businesses a head start.

What’s simpler than

It has already taken a long time to reach this point: your machine is finally ready for commissioning. During the commissioning process missing functions and errors appear. This leads to further programming and testing loops, continuously delaying the project.

By working with Selmo, you can prevent countless hours of troubleshooting and testing loops. Our approach enables you to attend to your process and the Selmo Solution takes care of the rest, which means translating your process into PLC code. This way, you can ensure that all desired machine functions are available. Quickly gain insights by checking all the required functionalities early in the process by virtually commissioning your machine.

With Selmo, machine programming has become a whole lot faster and easier. Many clients have already successfully implemented the Selmo Solution in their digitalization projects. The entire digitalization in mechanical engineering is finally possible, and as a great side effect, you save time, costs & nerves - from now on, simply with Selmo.

Few like to address it, but the numbers speak for themselves: According to the 2022 Senseye study, unplanned downtime and production stoppages are...

Machines are at the core of every manufacturing company. They are the driving force behind the efficiency and success of a production line. However,...

.png)

Lost in Translation? SELMO – ONE digital language that makes machines truly digital. For companies to benefit from all the advantages of digitization...