1 min read

Find out what Selmo Technology is capable of

Controllable systems for safe and reliable production processes Every machine or plant in today's digital world consists of zeros and ones. Every...

1 min read

DI Markus Gruber

:

Feb 14, 2024 11:01:36 AM

DI Markus Gruber

:

Feb 14, 2024 11:01:36 AM

Machines are at the core of every manufacturing company. They are the driving force behind the efficiency and success of a production line. However, behind the shiny surfaces and the apparent smooth operation often lies an invisible threat: unknown errors.

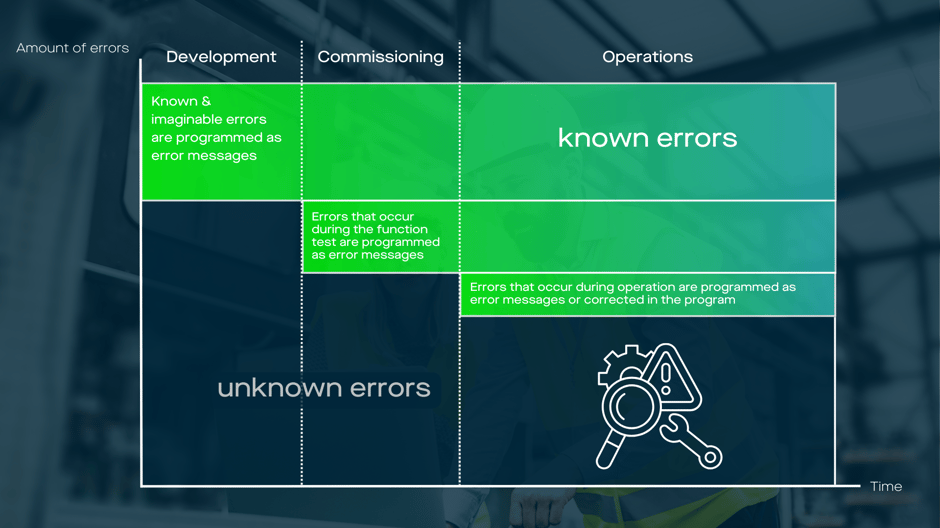

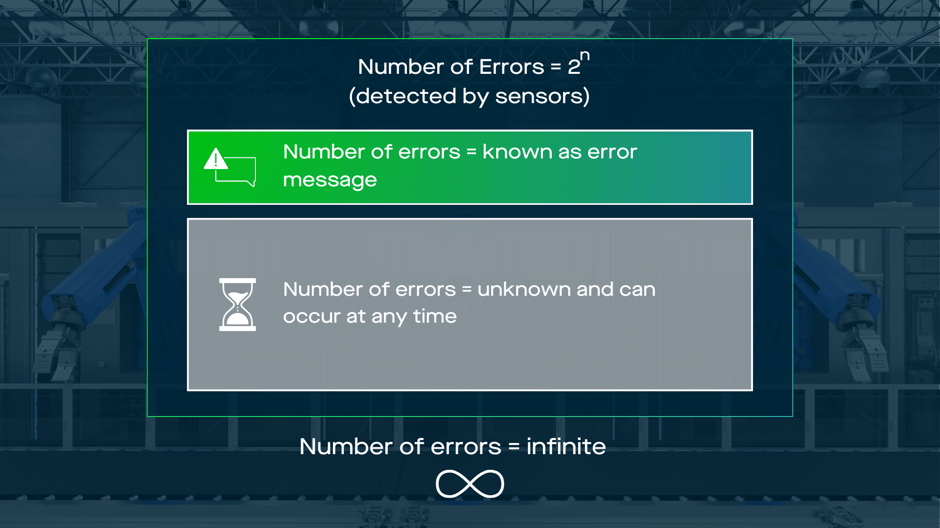

It's a bitter reality that every company operating production machinery is burning money daily without even realizing it. These machines are often fraught with a significant unknown error source, which accumulates into hidden costs over time. While known errors can be captured and resolved through error notifications, unknown errors often go undetected, leading to unplanned downtime, defective products, and internal maintenance costs.

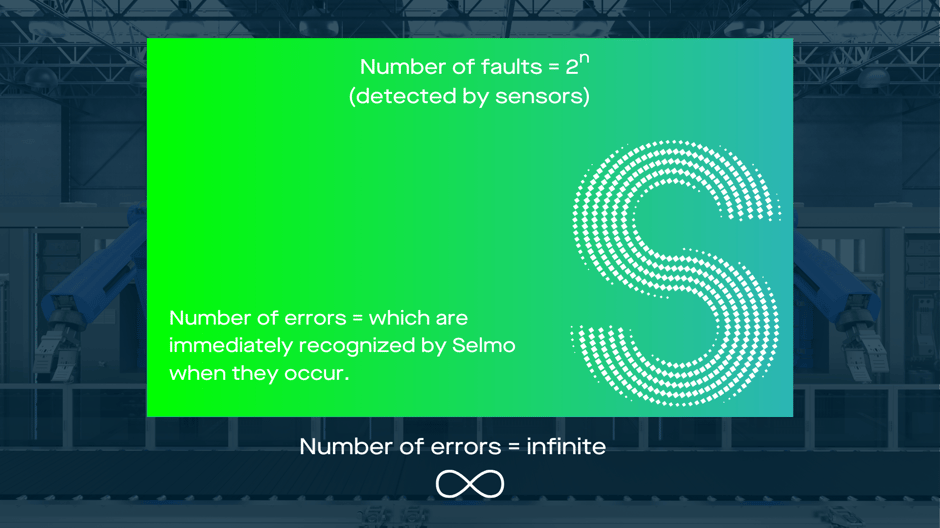

But what if there were a solution to this problem? What if we could identify and address every error, whether known or unknown, immediately? This is precisely where the Selmo method comes in. Based on a simple yet effective principle, it enables precise real-time error detection.

The Selmo method is based on the clear definition of an target state for each machine. By defining every permissible state and action, a precise process model is established. Any deviation from this model is recognized as an error. This approach allows not only for the capture of known errors but also for the identification of unknown errors without the need to program individual error messages.

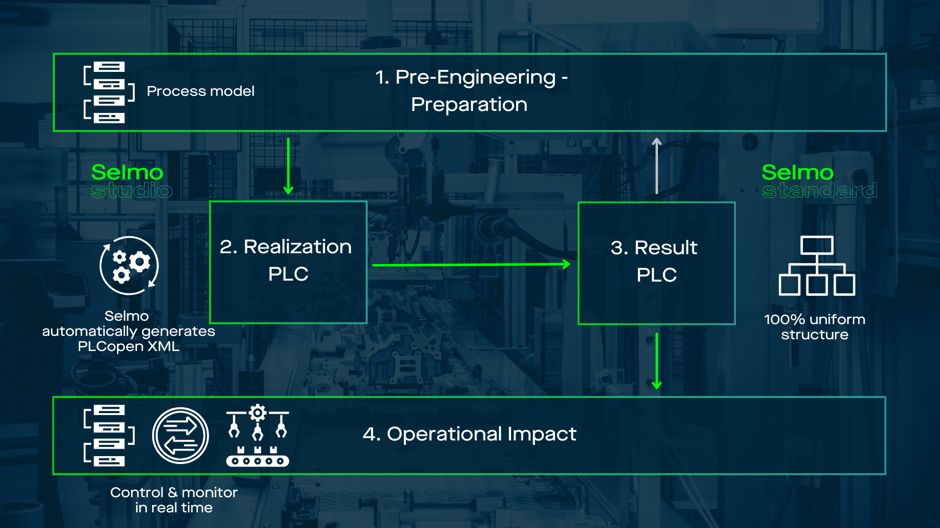

By implementing the Selmo Solution in your company, a seamless digitalization and automation concept is established, benefiting all people involved through a unified structure. From modeling the process model during the pre-engineering phase to automatically generating error-free code in PLCopen XML format during the implementation phase, commissioning, and real-time control and monitoring of machine behavior, synergies are created, allowing for simplified collaboration in every phase.

It's time to question the status quo and introduce a new era of machine automation. With the Selmo method, companies can not only capture the known errors in their machines but also the invisible dangers lurking in the shadows. It's time to make unknown errors visible and shape a future where automation runs smoothly and efficiently.

Gain a fascinating insight into the Selmo Solution through a free online presentation.

1 min read

Controllable systems for safe and reliable production processes Every machine or plant in today's digital world consists of zeros and ones. Every...

Few like to address it, but the numbers speak for themselves: According to the 2022 Senseye study, unplanned downtime and production stoppages are...

.png)

Lost in Translation? SELMO – ONE digital language that makes machines truly digital. For companies to benefit from all the advantages of digitization...