Downtime

The cost trap of machine downtime: Why a new look at PLC programming is necessary. When machines come to an unplanned standstill, they burn up a lot...

2 min read

DI Markus Gruber

:

Apr 19, 2023 12:06:10 PM

DI Markus Gruber

:

Apr 19, 2023 12:06:10 PM

In the control development process, programming is a critical step that often takes time and resources. Traditionally, control programming is done manually by the programmer. This manual step can cause errors that slow down the process. However, in recent years, automatic programming has emerged as a promising alternative in software development.

This blog post will look at the benefits of switching to automatic programming in control development.

Automatic programming enables faster and more efficient creation of control programs. Using standardized and pre-built code libraries allows developers to save time and focus on other tasks.

Since automatically generated programs are based on standardized processes and libraries, they are error-free and meet all requirements. This leads to higher quality and reliability of control programs.

The higher efficiency and quality of automatically generated programs lead to higher productivity in control development. As a result, companies can create more programs in less time and focus on other vital projects.

By using automatic programming, the risk of errors and downtime is reduced. In addition, automatically generated programs are thoroughly tested and meet all requirements leading to higher reliability and lower risk of downtime and production losses.

Switching to automatic programming has many benefits, but it also requires a certain amount of preparation, such as retraining employees, selecting the right tools, and adapting existing workflows. However, the switch is worth it because companies benefit from higher efficiency, quality, productivity, and lower risk.

Automatic programming is a promising alternative to manual programming in control development. Companies should consider this option to reduce the risk of downtimes and production losses.

The Selmo Solution offers more than just automatic control programming. It is a comprehensive solution that takes machine programming to a new level.

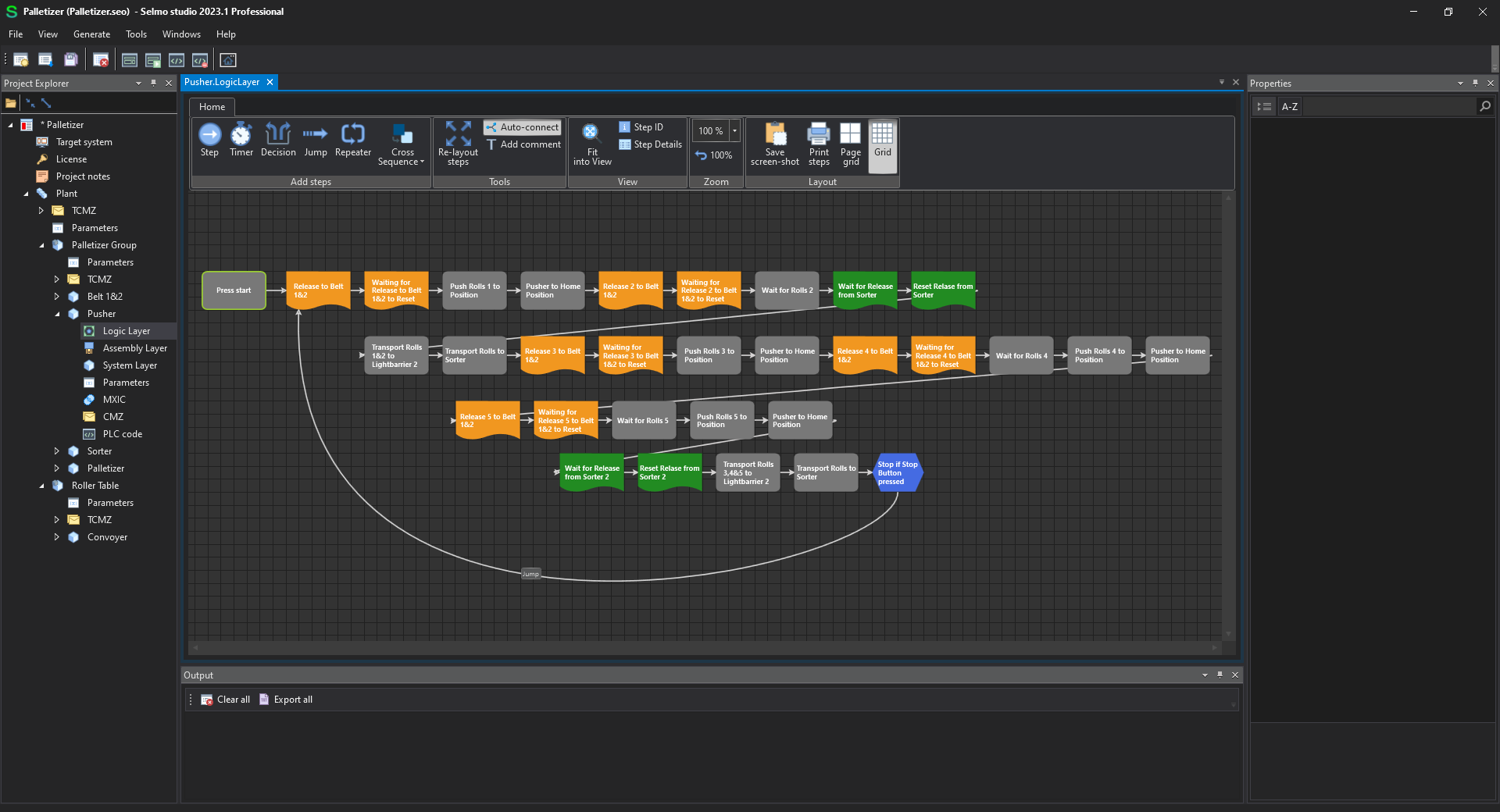

Selmo creates an open and transparent programming standard – the Selmo Standard, which includes all essential functions and ensures uniform structures. To ensure the standard is maintained, we have created a development tool – the Selmo Studio, which allows the programmer to connect signals and logical processes.

Within the Selmo Studio, you can model your process instead of manually writing code. The process is automatically translated 1:1 without an intermediate step. The result is a PLCopen XML format that can be imported into any programmable logic controller that supports international standards.

Using the Selmo Standard as a framework and Selmo Studio as a tool ensures that the standard is 100% adhered to without the programmer having to worry about it. At the same time, sufficient freedom is left in the programming, in which the logical sequence can be freely designed. In addition, the Selmo method removes the randomness from the programming by defining all states and only the modeled process as a valid target state.

Besides the automatically generated PLC program, the visualization (HMI) is also generated without manual programming effort. This results in a uniform operating concept that enables the safe handling of the machines for every operator and maintainer.

This approach allows programmers to focus on their own core competence, namely programming the drivers. Selmo creates the basis in the form of a uniform structure and still leaves enough room for flexibility and specific requirements.

Selmo is not a stand-alone solution. Instead, it is a integrated concept for reliable software in mechanical engineering with the Selmo Standard as a framework, the Selmo Studio as a tool for implementation, and a hardware-independent program in the form of PLCopen XML as a result.

The rapid implementation of machine software changes the project phases in mechanical engineering and allows users to benefit from the full potential of digitalization.

A minor change in programming methodology with a significant impact on the entire project workflow - faster & easier to the finish line with Selmo.

.png)

The cost trap of machine downtime: Why a new look at PLC programming is necessary. When machines come to an unplanned standstill, they burn up a lot...

You probably know this situation:Suddenly, a machine comes to a halt. No one knows why. The team is waiting, the delivery deadline is approaching –...

.png)

Optimizing machines and production processes is a crucial factor for a company's success across the entire industry. In this blog post, we explain...